In recent years, denturism has evolved with the ever-growing world of technology. With the profession previously being limited to constructing prostheses and dental implants entirely by hand, the innovation of 3-D printing is beginning to change the way denturists approach dental repair.

With the use of 3-D printing penetrating the industry, those looking to enter the field will be able to use this technology in order to better remedy a patient’s condition. Here’s what professionals should know about this manufacturing procedure.

What is 3-D Printing and How Does it Work?

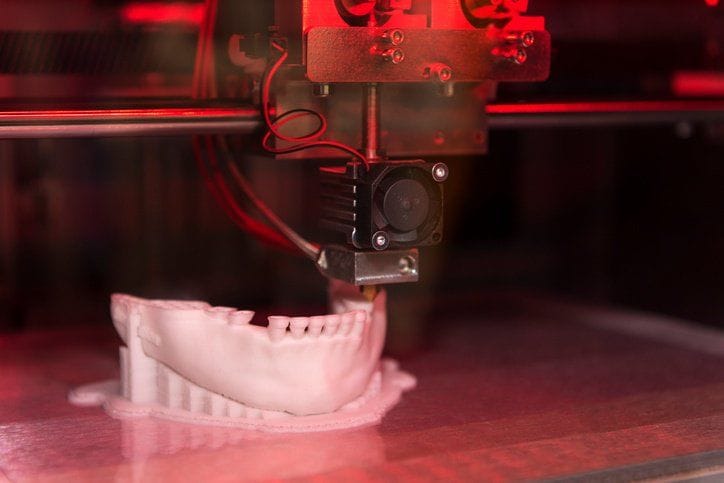

3-D printing is a relatively new method that denturists are using to design and develop dentures for patients. It is an innovation that is making the development of prosthetics easier, quicker, and more accurate for both professionals and their clients. The process consists of scanning the patient’s upper and lower teeth, as well as performing a bite scan to accurately tailor the design of the denture to the patient’s mouth.

3-D printers produce dentures after the design is scanned

After the scanning is refined, which usually takes 2 to 3 minutes, the design takes place using a computer aided design (CAD) program. Once the printer begins printing, molten thermoplastic polycarbonate is released into layers. These layers are placed on top of one another in order to build each component. Each molten plastic layer is placed on top of the previous one and flattened by the extrusion head, fusing each part together instantly. This method makes it easier for these intricate component parts to be produced.

Students enrolled in a denturist course may find that many patients prefer this scanning procedure over the traditional method of having them bite down on material to make an impression, which some may find distasteful or uncomfortable.

What 3-D Printing Means for your Denturist Career

The introduction of 3-D printing in dentistry has brightened the future of the profession due to the many advantages it offers for patients, dentists, and denturists. The work produced with the use of this innovation is more stable, durable, and consistent.

Another major advantage of implementing 3-D printing in denture design and manufacture is the time-saving factor. Once the scanning has been produced, a digital copy is sent to the dental lab or 3-D printing organization within minutes and the technician can begin working on the denture immediately. Since it is done electronically, the process is completed in a clean, sanitary environment, and much of the cost of manufacturing materials and labour is reduced.

Technicians can work on 3-D printed molds without excess labor materials

All of this means that those pursuing or beginning a denturist career will enter the profession at an exciting time. Working with 3-D printing technology yields a more accurate and consistent end result and can reduce some of the problems that often come with traditional denture manufacture, such as the mistakes and inaccuracies that can occur due to how a patient is biting down, the duration of the bite, or inconsistencies in the material.

Are you interested in pursuing denturist training?

Contact Oxford College to learn more about our programs.